Page 6 - Kurtek Controls Catalog

P. 6

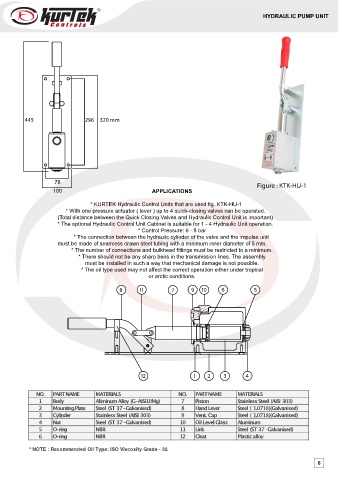

HYDRAULIC PUMP UNIT

! " # ! $ # !

## # " % & " !

445 296 320 mm

'! ( & ) $ ! $! " )! ! $! (! $

) ! ) #( ! ) "! #

# ( " (! $ !

$! $ # ! $! ! *$ &

# ! !

78 Figure : KTK-HU-1

100 APPLICATIONS

* KURTEK Hydraulic Control Units that are used fig. KTK-HU-1

! ) "! # ( ) " (! + $ (#

* With one pressure actuator ( lever ) up to 4 quick-closing valves can be operated.

! $! $(( ! $! $ # !

(Total distance between the Quick Closing Valves and Hydraulic Control Unit is important)

$! %( ! "" $! #

* The optional Hydraulic Control Unit Cabinet is suitable for 1 - 4 Hydraulic Unit operation.

! ( ! !

* Control Pressure: 6 - 8 bar

* The connection between the hydraulic cylinder of the valve and the impulse unit

must be made of seamless drawn steel tubing with a minimum inner diameter of 5 mm.

* The number of connections and bulkhead fittings must be restricted to a minimum.

* There should not be any sharp bens in the transmission lines. The assembly

must be installed in such a way that mechanical damage is not possible.

* The oil type used may not affect the correct operation either under tropical

) *$ & (! $ ! ) ) "! #

or arctic conditions.

$ ! " ) ! !

# $" $! !, ! " ! " & 9 10 6 5

11

8

7

-$! $ ! .- / 0# ! -$! $ 1" (( ) .0- /

& ) ! . / 2 !# ! & .2 / 3 4 !

! .34 / ) ! 5 4 . 540/

(! $

6 ! $ " $! ## # !

2

3

4

1

12

! & $ ! & ## #

& ! ) $! %( ! 7

NO. PARTNAME MATERIALS NO. PARTNAME MATERIALS

1 Body AliminumAlloy (G-AISi10Mg) 7 Piston StainlessSteel (AISI 303)

2 MountingPlate Steel (ST 37-Galvanised) 8 HandLever Steel ( 1.0718)(Galvanised)

3 Cylinder StainlessSteel (AISI 303) 9 Vent. Cap Steel ( 1.0718)(Galvanised)

4 Nut Steel (ST 37-Galvanised) 10 OilLevelGlass Aluminum

5 O-ring NBR 11 Link Steel (ST 37-Galvanised)

6 O-ring NBR 12 Cleat Plasticalloy

* NOTE : Recommended Oil Type: ISO Viscosity Grade - 32

6